How to Build a Durable Business Car Park: 6 Key Steps for Long-Term Performance

Why Car Park Construction Should Be a Business Priority

A poorly built car park can lead to cracking surfaces, dangerous potholes, frequent repairs, and even reputational damage. On the other hand, a well-constructed commercial car park reflects professionalism, improves customer experience, and reduces long-term costs.

Whether you’re a business owner planning a new development, or a facilities manager upgrading existing infrastructure, understanding the essentials of durable car park construction will save you time, money and hassle.

In this blog, we’ll explore the 6 key steps to building a long-lasting business car park, answer common questions, and offer professional insights that apply directly to UK businesses — from retail parks and offices to industrial estates and hospitality venues.

1. Start with a Ground Investigation

Before a single digger arrives on-site, a ground investigation is essential. This ensures the car park is built on a stable, load-bearing surface that can withstand both usage and weather over time.

Common assessments include:

- Soil type and bearing capacity

- Water table levels

- Contamination or drainage issues

- Existing infrastructure like cables or drainage systems

💡 Neglecting this stage leads to premature surface failure or subsidence, both of which are costly to fix.

2. Choose the Right Sub-Base

The sub-base is the hidden hero of any durable car park. It must:

- Distribute weight evenly

- Prevent surface cracking

- Provide drainage support

For most commercial applications, a Type 1 MOT sub-base is used. In high-traffic areas, a geogrid reinforcement may be added to boost structural integrity.

| Surface Type | Recommended Sub-Base Depth |

|---|---|

| Light car traffic | 150mm |

| Mixed car/van use | 200mm |

| Heavy-duty HGV zones | 250–300mm+ |

🛠️ Compaction is critical — sub-bases must be machine-compacted in layers to prevent sinking or movement.

3. Plan for Effective Drainage

Standing water not only looks bad — it weakens the surface and causes frost damage in winter. All business car parks should incorporate:

- Falls and cambers for surface runoff

- Permeable paving or attenuation tanks in SuDS (Sustainable Drainage Systems) zones

- Linear channel drains and gulleys at low points

🌧️ In the UK, rainfall is unpredictable — good drainage ensures safety and reduces maintenance headaches.

4. Surface Selection: Tarmac, Concrete or Block Paving?

The right surface depends on your budget, traffic levels and aesthetic goals.

| Surface Type | Best For | Pros | Cons |

|---|---|---|---|

| Tarmac | Retail, office and school car parks | Fast to install, cost-effective | Needs regular maintenance |

| Concrete | HGV or industrial yards | Highly durable, low upkeep | More expensive, slower to lay |

| Block paving | Visitor or high-end spaces | Attractive, easy to repair | Weeds, movement if laid poorly |

🚧 All surfaces must be installed by experienced contractors using high-quality materials — corners cut here will show fast.

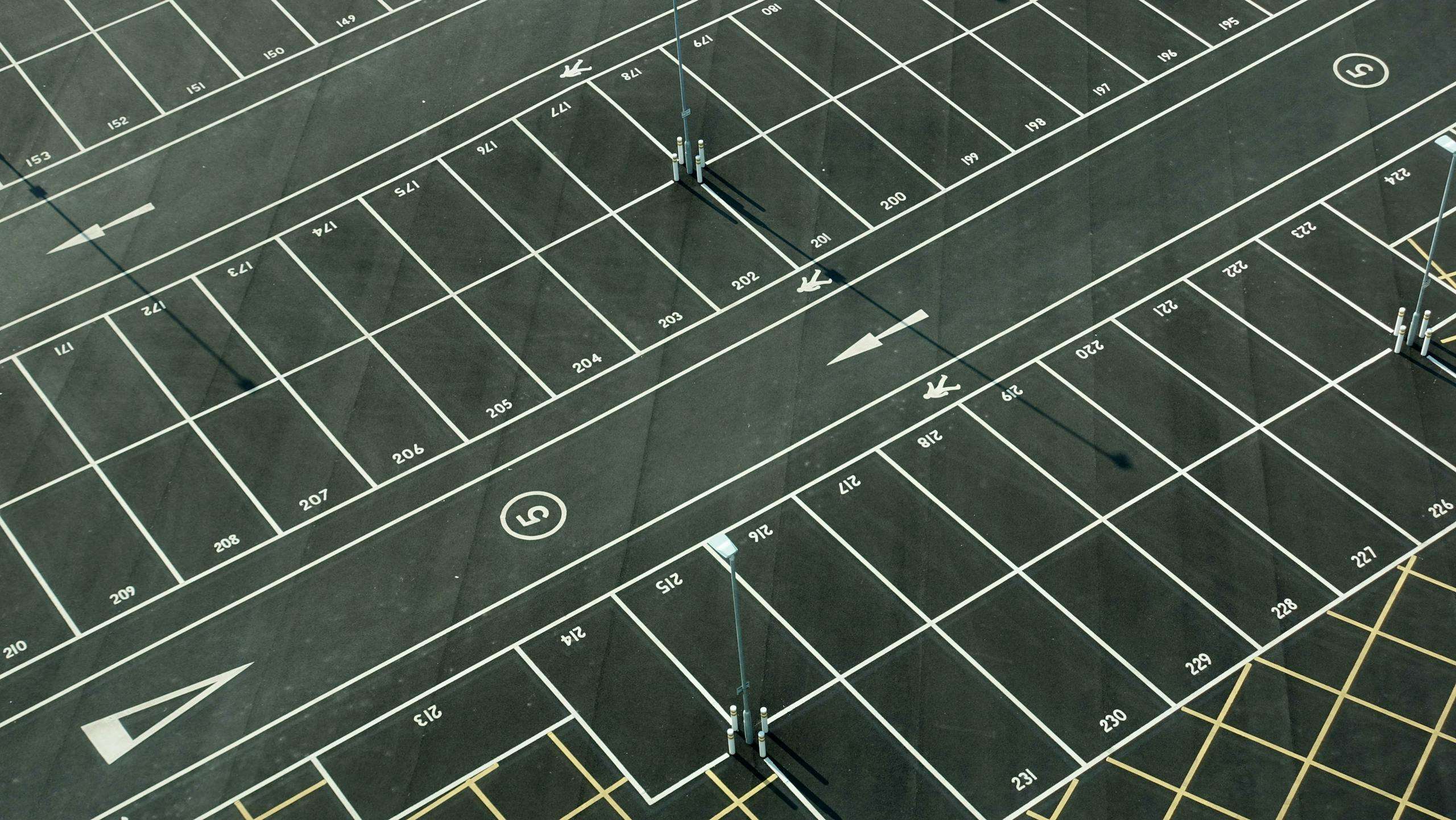

5. Add Line Markings, Kerbing & Signage

A finished car park isn’t just about the surface — it must also be functional and compliant. Consider:

- Bay line markings (standard, parent/child, disabled, electric vehicle bays)

- Directional arrows and speed signs

- Dropped kerbs and tactile paving for DDA compliance

- Safety barriers or bollards

Clear, durable markings reduce confusion and risk of accidents — especially in multi-use car parks or mixed vehicle/pedestrian zones.

🧩 Use thermoplastic or MMA line markings for durability — cheaper paints wear quickly in high-traffic areas.

6. Maintenance Planning and Aftercare

Even the best car park requires ongoing care to maintain performance and appearance.

We recommend a basic maintenance plan including:

- Annual inspection of surface condition and drainage

- Line repainting every 2–4 years

- Surface sweeping to prevent build-up and blocked drains

- Crack sealing before water ingress causes structural issues

⚠️ Ignoring early signs of wear results in more costly interventions down the line.

Frequently Asked Questions

How long should a commercial car park last?

With proper construction and routine maintenance, a tarmac surface should last 15–20 years, while concrete can exceed 30 years.

Can I upgrade an old car park or do I need to rebuild?

In many cases, a full rebuild isn’t necessary. If the sub-base is sound, resurfacing and remarking can restore performance and extend lifespan.

Is planning permission needed?

Small resurfacing jobs typically don’t need planning permission. However, new layouts, drainage changes or larger commercial developments may require approval.

Why Businesses Trust Professional Contractors

Choosing a contractor with commercial car park experience is key. At Killingley, we combine structural precision with long-term value — delivering surfaces that not only last but support your brand, safety and sustainability goals.

Our services include:

- Full design and layout consultation

- SuDS-compliant drainage solutions

- Durable surfaces and premium finishes

- Line marking, kerbing, bollards and lighting

Build Once, Build Right

A business car park is more than just somewhere to park — it’s a key part of your infrastructure. From daily customers and delivery vehicles to staff and service providers, it must stand up to constant use.

By following these six essential steps, UK businesses can ensure their car parks are durable, safe, cost-effective and fit for purpose — for decades to come.

Killingley Insights is the editorial voice of NT Killingley Ltd, drawing on decades of experience in landscaping, environmental enhancements, and civil engineering projects across the UK.