Cut & Fill Operations

Balancing Your Site, Maximising Your Budget

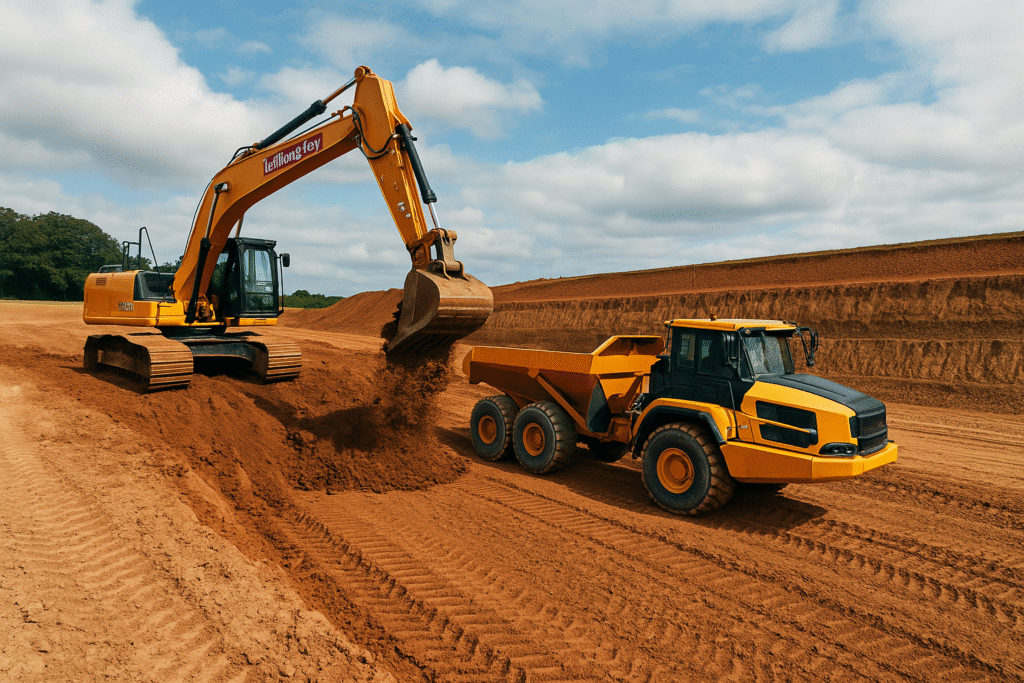

As part of our Technical Earthworks services, cut and fill operations play a vital role in shaping land to meet engineering requirements. These earthworks are essential for creating safe, stable, and build-ready platforms for commercial, residential, and infrastructure developments.

Effective cut and fill operations are fundamental to the success of any construction project involving land regrading. Whether you’re preparing ground for a new development or reshaping an existing site, the objective remains the same: achieve a level platform with minimal environmental impact and optimal cost-efficiency.

At NT Killingley, our cut and fill expertise helps streamline earthworks by balancing the volume of soil excavated (cut) with the amount needed to build up low-lying areas (fill). By planning and executing with precision, we reduce the need for imported or exported material, cutting haulage costs and reducing your project’s carbon footprint.

Key Components of Cut and Fill

Every cut and fill project is unique, but they generally follow a set of core phases:

The Importance of Accurate Planning

Planning is everything in cut and fill operations. With the use of 3D modelling and GPS machine control, Killingley ensures precise execution. Even slight inaccuracies in volume calculations can lead to expensive import/export adjustments later in the project.

Benefits of accurate planning include:

Our in-house engineering team works closely with clients to refine designs, assess geotechnical data, and forecast risks before any work begins.

Cut and Fill Techniques We Use

We apply a range of specialist methods to ensure safe, effective, and efficient ground reengineering:

Cut & Fill in Sustainable Development

Balancing earthworks isn’t just good practice – it’s sustainable. At Killingley, we take a responsible approach to materials management:

These practices support BREEAM, biodiversity net gain, and sustainable construction goals.

Applications Across Industries

Our cut and fill operations support a wide range of sectors:

Frequently Asked Questions

How long does a cut and fill project take? Timeframes vary depending on scale and ground conditions. A thorough survey and clear sequencing plan help avoid delays.

Is planning permission required? Significant earthworks may require planning consent, particularly in protected areas or near watercourses.

Can existing soil be reused? Yes. We test and, where necessary, improve site-won soils to meet compaction and structural requirements.

What if I need to remove excess material? Killingley has the capacity to manage surplus material responsibly, including off-site transport and recycling.

Can you work on sloped or complex sites? Absolutely. Our expertise includes working on varied terrain with slope stabilisation and reinforced structures.

Why Choose Killingley for Cut and Fill Operations?

Killingley brings a depth of technical earthwork experience, backed by ISO-accredited processes and state-of-the-art machinery. We work with architects, civil engineers, developers, and contractors to deliver cut and fill projects that are on budget, on programme, and environmentally responsible.

Our team integrates planning, surveying, modelling, and execution to provide a seamless service with exceptional outcomes.

From small-scale levelling to multi-hectare platforms, we offer the skill, equipment, and insight to unlock the full potential of your site.